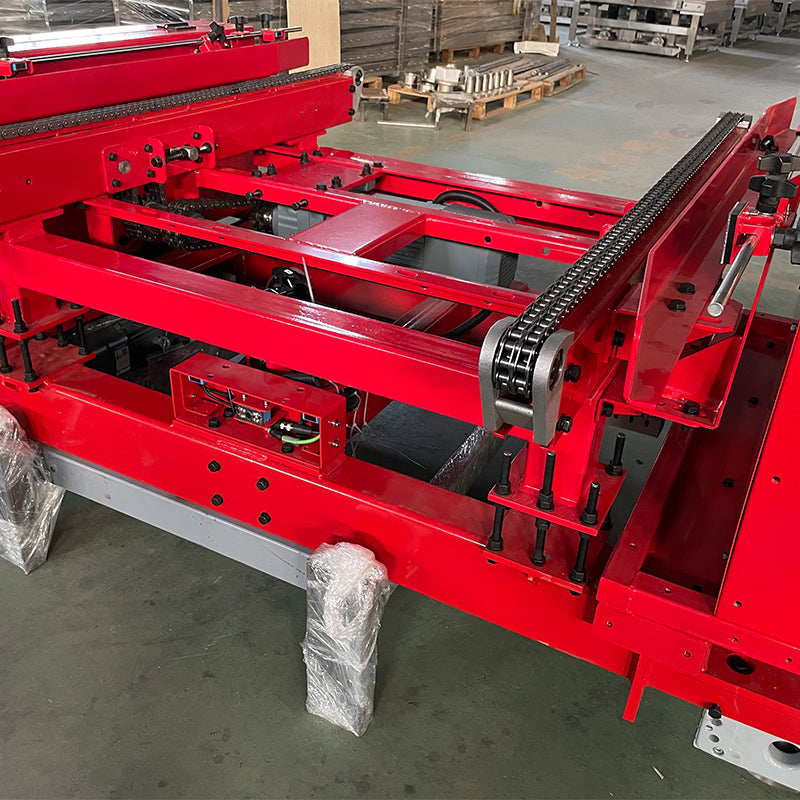

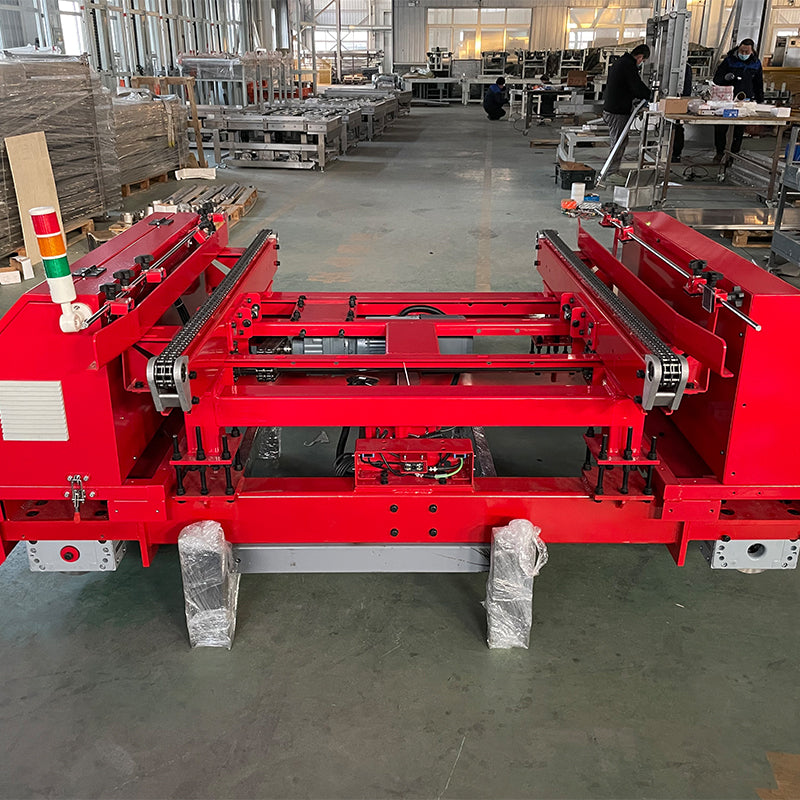

Light load RGV rail car

1 RGV rail car introduction:

Technical Parameters

|

project |

Technical Parameters |

|

|

Body shape (L×W×H) (㎜) |

Design size shall prevail (conveying surface 800mm) |

|

|

Rated load mass (Kg) |

>1000kg(single station) |

|

|

Transfer speed (m/min) |

0-16m/min |

|

|

Walking speed |

No-load speed (m/min) |

120 m/min |

|

No-load acceleration (m/sec2) |

0.5m/sec2 |

|

|

Load speed (m/min) |

0-100 m/min |

|

|

Load acceleration (m/sec2) |

0.5m/sec2 |

|

|

Positioning accuracy for no-load walking |

士5mm |

|

|

Load walking positioning accuracy |

士5mm |

|

|

Control System |

Siemens PLC control |

|

|

Power Specifications |

380/220V three-phase five-wire system |

|

|

noise |

70dB |

|

|

host color |

According to Party A’s color code |

|

Shuttle vehicle (RGV) control mode: manual, stand-alone and online automatic mode

⑴.Online automatic

When the system is running normally, the online automatic mode is adopted. The RGV receives the operation instructions of the conveyor through the wireless client, completes the corresponding operation, and feeds back the operation status information and fault information to the control computer.

⑵.Semi-automatic

The semi-automatic mode is a decomposition of the operation process of the automatic mode of the machine, which can complete operations such as moving, side shifting and transporting to a certain location in the roadway in a single step. This control method can be used when the RGV is running alone, when an abnormality occurs, or when it is installed and debugged.

⑶.Manual control

The manual mode is generally used in the installation and commissioning stage of RGV or the reset when RGV is abnormal, and can independently operate RGV running, side shifting, conveying, stacking, resetting, and dismantling.

⑷.Maintenance methods

Ignore most errors and only use it when debugging and when the device fails to run normally.

Positioning device: LEUZE or SICK, laser barcode addressing;

The sensor installed on the RGV constantly monitors the position information, and calculates whether it is in place. It has the function of automatic addressing.

Wireless communication: MOXA, H3C

RGV-PLC communicates with the ground control system by means of wireless communication through MOXA and H3C clients.

The wheels are non-standard customized, the track is made of aluminum alloy track, and double guide rails; the motor is made of German Nord or SEW motor

The sensor brand adopts P+F, Banner or SICK, and the low-voltage electrical appliance brand adopts Schneider.

When the shuttle fails during the execution of instructions, the system has the function of releasing and reassigning instructions.

The shuttle car has safety protection and safety alarm functions, and can automatically reset and resume work after the obstacle is removed; the shuttle car is required to be equipped with an emergency stop button and have sound and light warning devices.

The conveying rib is made of stainless steel, with an adjustable range of ±10mm.

The operating space of the shuttle car is fully enclosed by safety guardrails. The height of the safety net is 1.2 meters, and there is a safety door. When the door is opened, the whole line stops. When the door is closed and reset manually, the system continues to perform the original operation. The color of the protective net is specified by the customer.

RGV adopts tubular trolley line power supply tubular trolley line, including double collector

Shuttle car safety protection: There is a laser safety scanner at the front and rear, using LEUZE company products.

Control System

The shuttle has an independent electronic control system. The shuttle is equipped with a control cabinet. A Siemens series PLC is installed in the cabinet for signal collection and related output control. The collected signals are sent to the ground control system of the small three-dimensional warehouse through optical communication. And receive the task scheduling of the small piece ground control system. The shuttle car has emergency stop, fault alarm and various safety protection functions.